STIKO Deadweight Testers

Deadweight testers are the basic primary standard for accurate measurement of pressure. The STIKO deadweight testers are used to measure the pressure exerted by gas or liquid and can also generate a test pressure for the calibration of numerous pressure instruments.

No other device can match the stability, repeatability and accuracy of a deadweight tester.

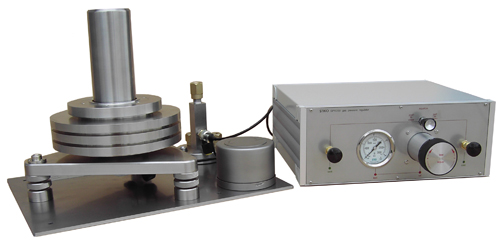

DOS001 – Hydraulic Operated DWT

- This is a stainless steel deadweight tester.

- Ranges up to 1400 bar (20.000 psi).

- Compact and rugged design.

- Accuracy: 0,01% of reading.

General Specifications

pressure range 0,5 .. 50 / 2 .. 200 MPa g

measurement uncertainty p 1.10-4.pe + 100 Pa

certification standard delivered with EA1 certificate

pressure connections 3/8” BSP LH with BSP adapters

platform stainless steel triangle shape

footprint base plate 520 x 320 mm

overall height 315 mm

pressure media oil DWT oil 812

Piston Cylinders

material cylinder tungsten carbide

material piston tungsten carbide special steel

nominal piston diameter 5 2,5 mm

nominal Kn 500 kPa/kg 2 MPa/kg

thermal expansion 9.10-6 11.10-6 oC-1

type re-entrant

medium oil operated / oil lubricated

certification EA calibrated on effective area

A dead weight tester apparatus uses known traceable weights to apply pressure to a fluid for checking the accuracy of readings from a pressure gauge. A dead weight tester (DWT) is a Calibration standard method that uses a piston cylinder on which a load is placed to make an equilibium with an applied pressure underneath the piston. Deadweight testers are Primary Standards which means that the pressure measured by a deadweight tester is defined through other quantities: length, mass and time. Typically deadweight testers are used in calibration laboratories to calibrate pressure transfer standards like electronic pressure measuring devices.

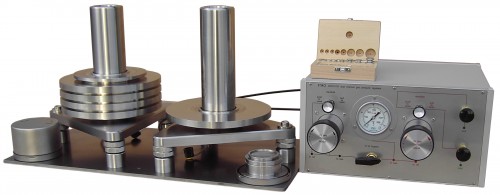

DOS0008 – Hydraulic Operated DWT |

| This is a stainless steel deadweight tester. | ||

| Ranges up to 1400 bar (20.000 psi). | ||

| Compact and rugged design. | ||

| Accuracy: 0,008% of reading. | ||

General Specifications

pressure range 0,5 .. 50 / 2 .. 200 MPa g

measurement uncertainty p 0.8.10-4.pe + 100 Pa

certification standard delivered with EA1 certificate

pressure connections 3/8” BSP LH with BSP adapters

platform stainless steel triangle shape

footprint base plate 520 x 320 mm

overall height 315 mm

pressure media oil DWT oil 812

LCD thermometer measures the piston / cylinder temperature °C

Piston Cylinders

material cylinder tungsten carbide

material piston tungsten carbide special steel

nominal piston diameter 5 2,5 mm

nominal Kn 500 kPa/kg 2 MPa/kg

thermal expansion 9.10-6 11.10-6 oC-1

type re-entrant

medium oil operated / oil lubricated

certification EA calibrated on effective area

coming soon

DOS0015 – Hydraulic Operated DWT |

| This is a stainless steel deadweight tester. | ||

| Ranges up to 1400 bar (20.000 psi). | ||

| Compact and rugged design. | ||

| Accuracy: 0,015% of reading. |

General Specifications

measurement uncertainty p* 1.5 ·10-4 · pe (of reading)

certification standard delivered with company certificate (EA1 traceable)

pressure connection 3/8” BSP LH with BSP adapters

footprint base plate 340 (w) x 225 (d) mm

maximum size 340 (w) x 430 (d) mm

overall height (excl. weights) 210 mm

overall height (incl. weights) Max. 450 (depending on range)mm

pressure media oil DWT oil Nuto H 32 Esso

coming soon

DGS-001 – Laboratory Differential DWT |

| This is a Gas operated / liquid lubricated deadweight tester with a hard metal tungsten carbide piston cylinder assembly. | ||

| Ranges up to 200 bar (3.000 psi). | ||

| Accuracy: 0,01% and 0,008% of reading. |

General Specifications

pressure range 0 .. 20 MPa g

differential pressure range 0 .. 20 MPa d

measurement uncertainty p 1.10-4.pe + 10 Pa

certification standard delivered with EA1 certificate

max. supply pressure 25 MPa g

pressure connections ¼” BSP female2

platform stainless steel triangle shape

footprint base plate 425 x 320 mm

overall height 315 mm

lubricating oil DWT oil 812

Piston Cylinder

material piston + cylinder tungsten carbide

nominal piston diameter 5 mm

nominal Kn 500 kPa/kg

thermal expansion (p+c) 9.10-6 oC-1

type re-entrant

medium gas operated / oil lubricated

certification EA calibrated on effective area

Mass Set

description nominal mass nominal pressure

mass carrier (piston mass included) 1 kg 5 bar

4 kg 20 bar

2 kg 10 bar

1 kg 5 bar

500 g 2.5 bar

200 g 1 bar

100 g 0.5 bar

optional*

50 g 250 mbar

20 g 100 mbar

10 g 50 mbar

5 g 25 mbar

2 g 10 mbar

1 g 5 mbar

certification EA certification on conventional mass

* optional small mass set

1

coming soon

DGDP001 – Laboratory Differential DWT |

| This is a Gas operated / liquid lubricated deadweight tester with a hard metal tungsten carbide piston cylinder assembly. | ||

| Ranges up to 200 bar (3.000 psi). | ||

| Accuracy: 0,01% and 0,008% of reading. |

General Specifications

pressure range 0 .. 20 MPa g

differential pressure range 0 .. 20 MPa d

measurement uncertainty p 1.10-4.pe + 10 Pa

certification standard delivered with EA1 certificate

max. supply pressure 25 MPa g

pressure connections ¼” BSP female2

platform stainless steel triangle shape

footprint base plate 600 x 320 mm

overall height 315 mm

lubricating oil DWT oil 812

Piston Cylinders

Master Piston Cylinder

material piston + cylinder tungsten carbide

nominal piston diameter 5 mm

nominal Kn 500 kPa/kg

thermal expansion 9.10-6 oC-1

type re-entrant

medium gas operated / oil lubricated

certification EA calibrated on effective area

Slave Piston Cylinder

material piston + cylinder tungsten carbide

nominal piston diameter 5 mm

nominal Kn 500 kPa/kg

type re-entrant

medium gas operated / oil lubricated

certification none, selected on equal performance as master piston cylinder

coming soon

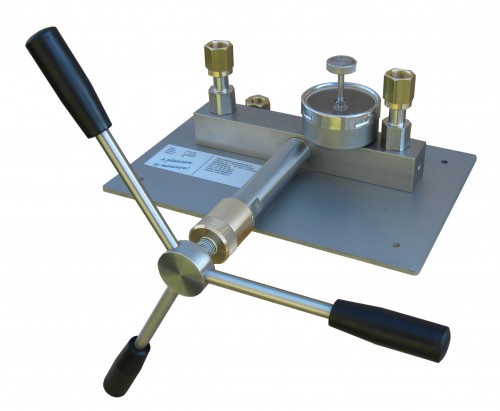

COP700 / 1400 – Comparison Test Pump |

| This product is used for checking instruments against master test gauges. | ||

| Easily primed. | ||

| Ranges up to 1400 bar ( 20.000 psi ). | ||

| 26cc volume displacements. | ||

| Medium: oil and water |

Specifications

type COP700 COP1400

maximum pressure 700 bar 1400 bar

footprint 340 mm (W) x 225 mm (D) 340 mm (W) x 225 mm (D)

height 130 mm 130 mm

pressure connections 3/8”bsp left handed male 3/8”bsp left handed male

female bsp adapters 1/2”; 3/8”; 1/4”; 1/8”; brass 1/2”; 3/8”; 1/4”; 1/8” stainless steel

medium Esso Nuto H32 Esso Nuto H32

piston displacement 24 cm3 24 cm3

coming soon

COP7000 – Comparison Test Pump |

| This product is used for checking instruments against master test gauges. | ||

| Easily primed. | ||

| Ranges up to 7000 bar ( 100.000 psi ). | ||

| 26cc volume displacements. | ||

| Medium: oil and water |

General Specifications

pressure range max. 700 MPa g

pressure media Sebacate oil

frame 460 x 405 x 370 (wxdxh) mm

outer dimensions 805 x 585 x 510 (wxdxh) mm

pressure connections gland M16x1,5

collar M6x0.75 LH

tubing HP-160 6 mm 700 MPa rated

valves 2 way straight 700 MPa R-V1-2-70

tee 700 Mpa rated R-F1-3-70

cross 700 MPa rated R-F1-4-70

screw pump 3 cc 700 MPa rated R-SP-70

overpressure protection head 100 MPa rated R-RDHM1-70

overpressure protection disc 100 MPa rated R-RD-1000

priming pump 70 MPa rated save upto overpressure disc

coming soon

GPR200 – Gas Pressure Regulator |

| Compact and easy to use system for manually setting and adjusting pressure. | ||

| For pressure- and differential pressure. | ||

| Maximum 20 MPa g. |

GPR200D – Gas Pressure Regulator |

| Compact and easy to use system for manually setting and adjusting pressure. | ||

| For pressure- and differential pressure. | ||

| Maximum 20 MPa g. |

GPR200SP – Gas Pressure Regulator |

| Compact and easy to use system for manually setting and adjusting pressure. | ||

| For pressure- and differential pressure. | ||

| Maximum 20 MPa g. |

GPR-S120 – Gas Pressure Regulator |

| The GPR-S-120 is designed to manually set and adjust gas pressures between atmosphere and 12 MPa in high line applications. For this the GPR-S-120 has 2 special regulating valves. | ||

| Compact and easy to use system for manually setting and adjusting pressure. | ||

| Maximum 20 MPa g. | ||

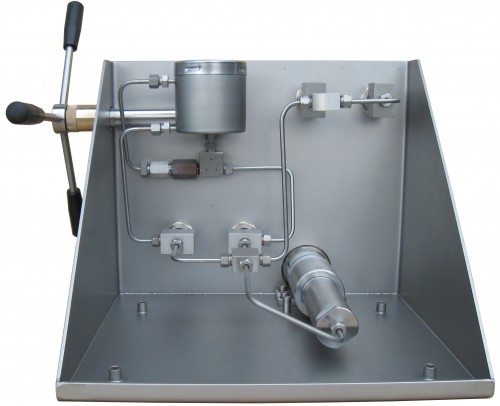

Fluid Distinguisher |

| 1. application The calibration of pressure transmitters at several temperatures with a maximum of 250°C and a maximum of 2000 bar. |

||

| 2. considerations The desired 250°C is higher than the flashpoint of the medium used in a deadweight testers (Sebacate) so a different fluid needs to be used in the heated part of the system. A physical separator is not desirable as this adds uncertainty to the system. |

||

| 3. solution The distinguisher does not have a physical barrier, but uses a mixing chamber with a lower and upper pressure port. The lower pressure port is dedicated to be connected to the process oil (high temperature Silicon oil) which has a higher density than the Sebacate oil used in the deadweight tester. The upper pressure port is used for connecting the Sebacate part of the system. The mixing chamber is also used for connecting additional safety devices. A pre hand pump is used to fill the system. |

||

Liquid Seperator |

| This liquid seperator can be used up to 2000 bar. The separator can be used in a calibration system with two different types of oil. The first oil is used in the deadweigh tester and the secound is used in the device under test. The liquid seperator does not have a physical barrier, but uses a mixing chamber with a lower and upper pressure port. The lower pressure port is dedicated to be connected to the process oil which has a higher density than the oil used in the deadweight tester. The upper pressure port is used for connecting the deadweight tester. | ||

![[bottom of graphic]](http://www.veronics.com/wp-content/themes/veronics/images/bg-mastbot.jpg)